Body Parts

Copter Parts STL files are designed for 3D printing.

- The primary printing method is FDM (filament) printing, although SLA (resin) and SLS (powder) may offer advantages for certain components.

- Most parts can be printed using common PLA filaments. Key filament characteristics include: Stiffness and Layer Adhesion.

While materials like ABS and PETG offer added strength—especially for parts like landing gear legs—the ease and low cost of reprinting parts means advanced materials may not be necessary.

I’ve used Polymaker PLA-Pro for most body parts. Its high stiffness helps reduce vibration, which is essential for quadcopter stability.

Flexible Body Parts using TPU

Parts that benefit from flexibility include:

- Battery tray door

- Landing gear feet

These can be printed with TPU filament, though both components are optional. You may also substitute the battery tray door with a simple battery strap.

Transparent Body Parts

Transparent materials offer visibility into the quadcopter’s internal electronics through the dome lid.

- The clearest results come from clear resin using SLA printing.

- Translucent PETG can also help you view LED indicators on internal components.

Vendors like PCBWay can produce this part with SLA resin and polishing for about $10.

Fasteners

Parts are assembled using standard screws:

- M3 screws for body components

- M2.5 screws for securing the XT-60 plug

Recommended fasteners:

| Fastener Type | Use Case |

| Metal M3 Flange Head | Attaching motors, Motor Mount Plate, Arms to Fuselage Body |

| Metal M3 Button Head | Provides clearance when attaching Motor Mount Plate to an Arm |

| Nylon M3 Phillips Head | Used in tapped holes for the Battery Tray and Landing Gear Legs |

| Metal M3 Nylock Nut | Secures Motor Mount Plates and Arms |

| Metal M3 Washer | Distributes load under Nylock nuts |

| Nylon M3 Standoff | Elevates Equipment Tray above the flight controller |

| Metal/Nylon M2.5 Screw | Secures XT-60 plug |

Adhesives and Adhesive Tapes

The only adhesive-required joint is attaching the lid to the dome—a few drops of hot glue work well. Hot glue has the advantage that it can be easily removed later by brushing on alcohol.

Common tapes used in sUAS builds:

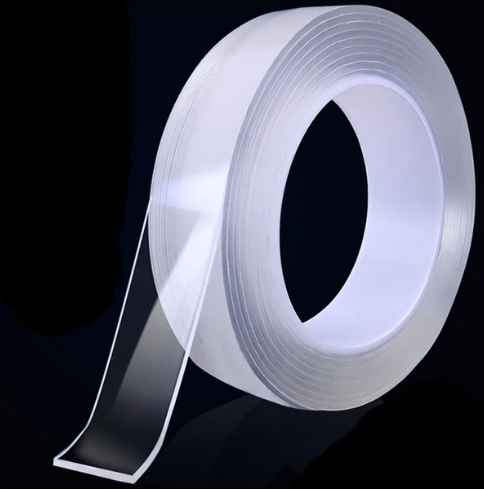

Double sided adhesive tapes are commonly used to attach electronics to surfaces. Some commonly used in sUAS construction are:

- 3M VHB – Thin, strong, and nearly permanent

- 3M Foam Tape – Strong and helps absorb vibration

- Double-sided “nano” tape – ~2mm thick, gummy, easy to remove, and holds well