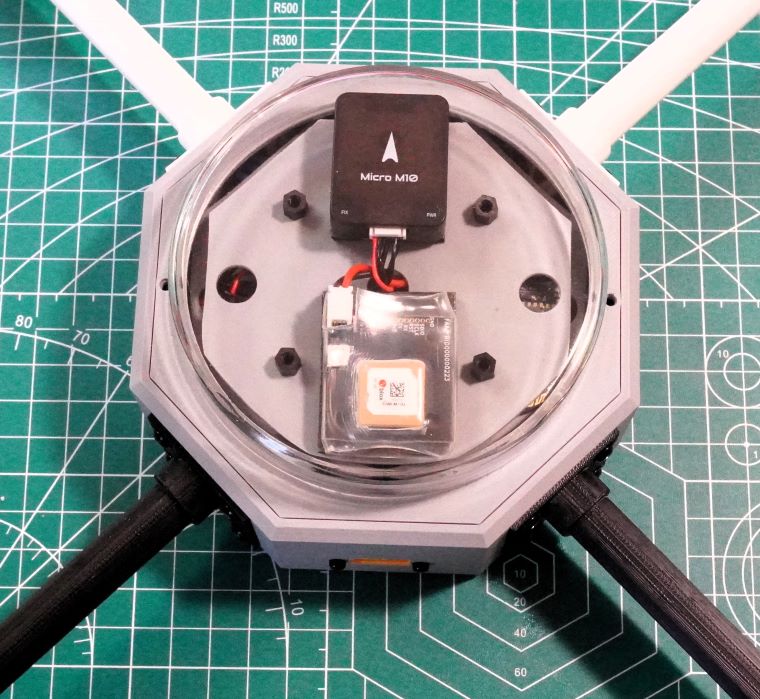

The builder must decide on the assembly methods that best suit them. These illustrated examples show only some of the possible ways to do the assembly.

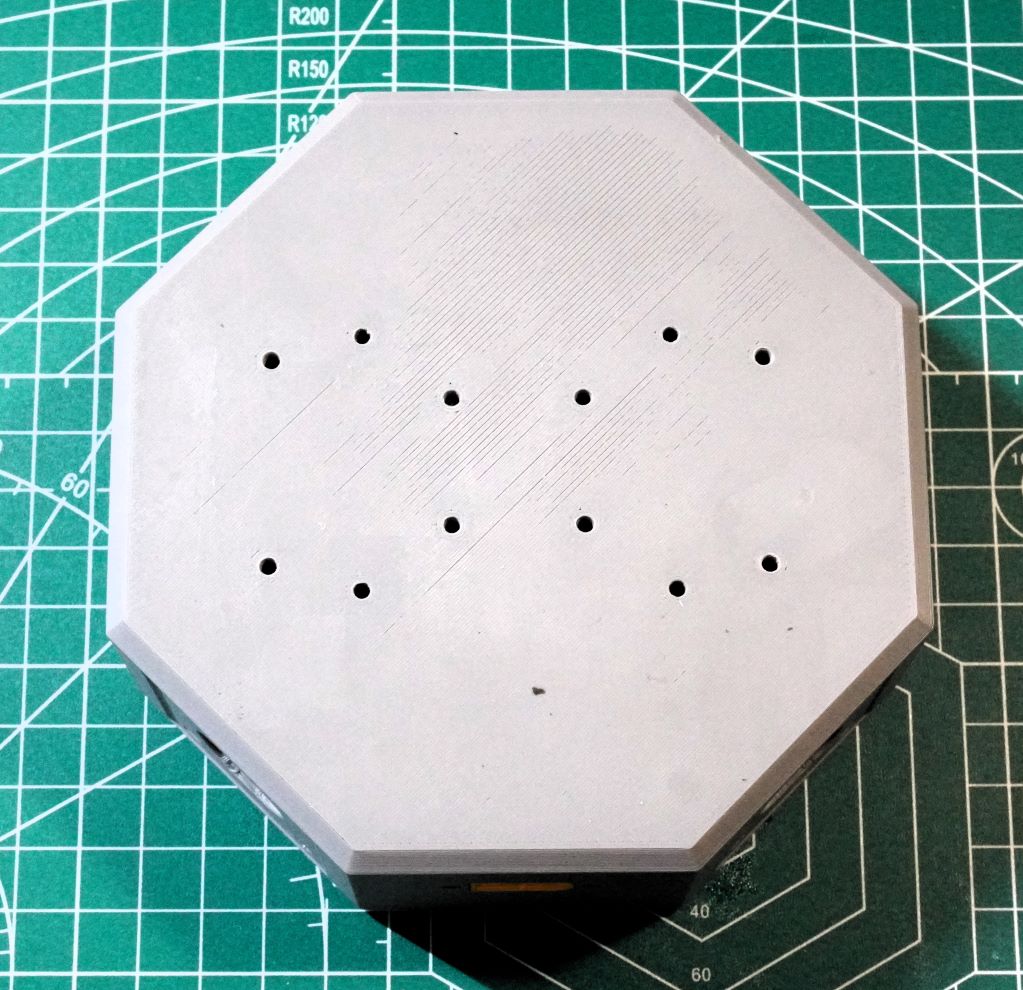

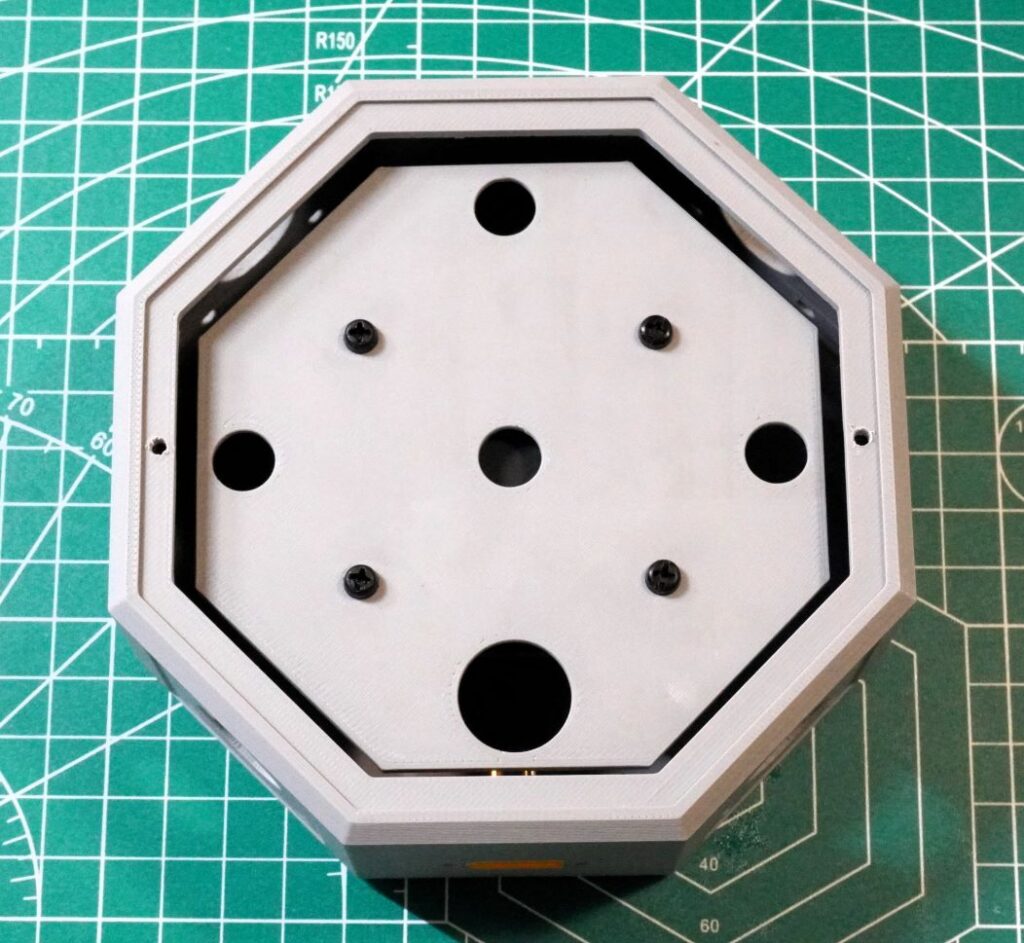

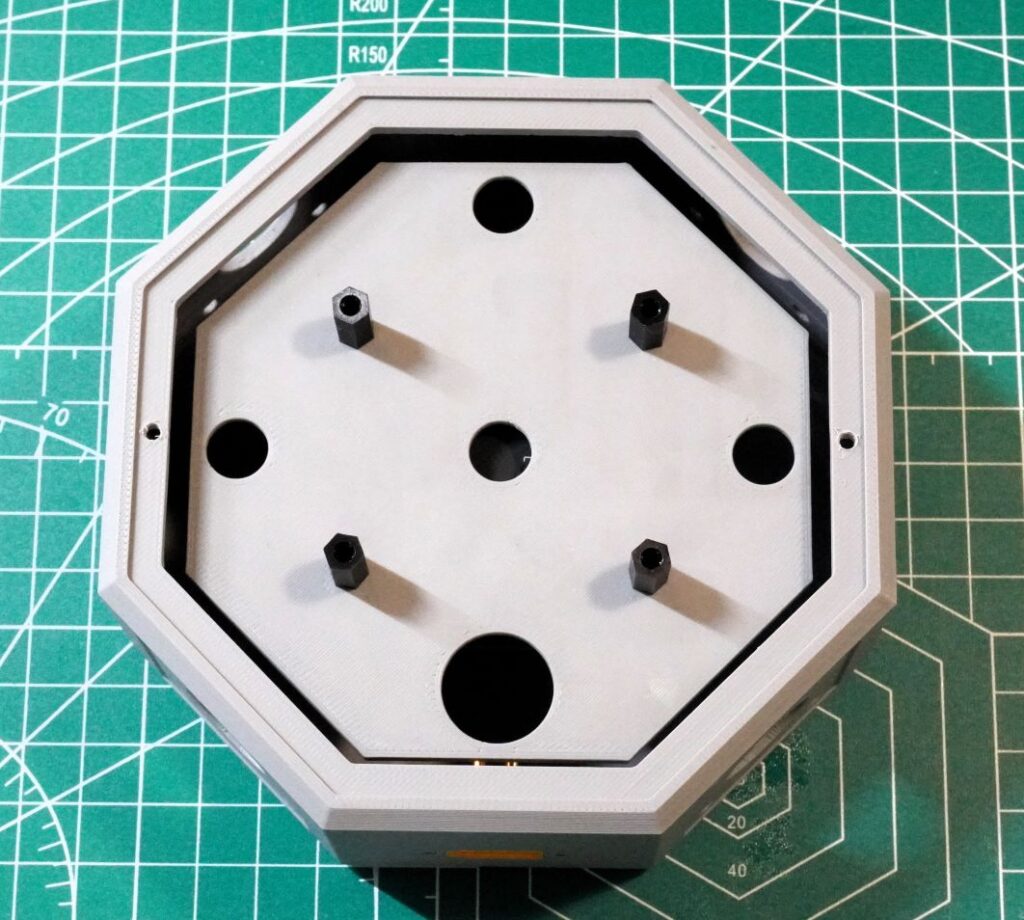

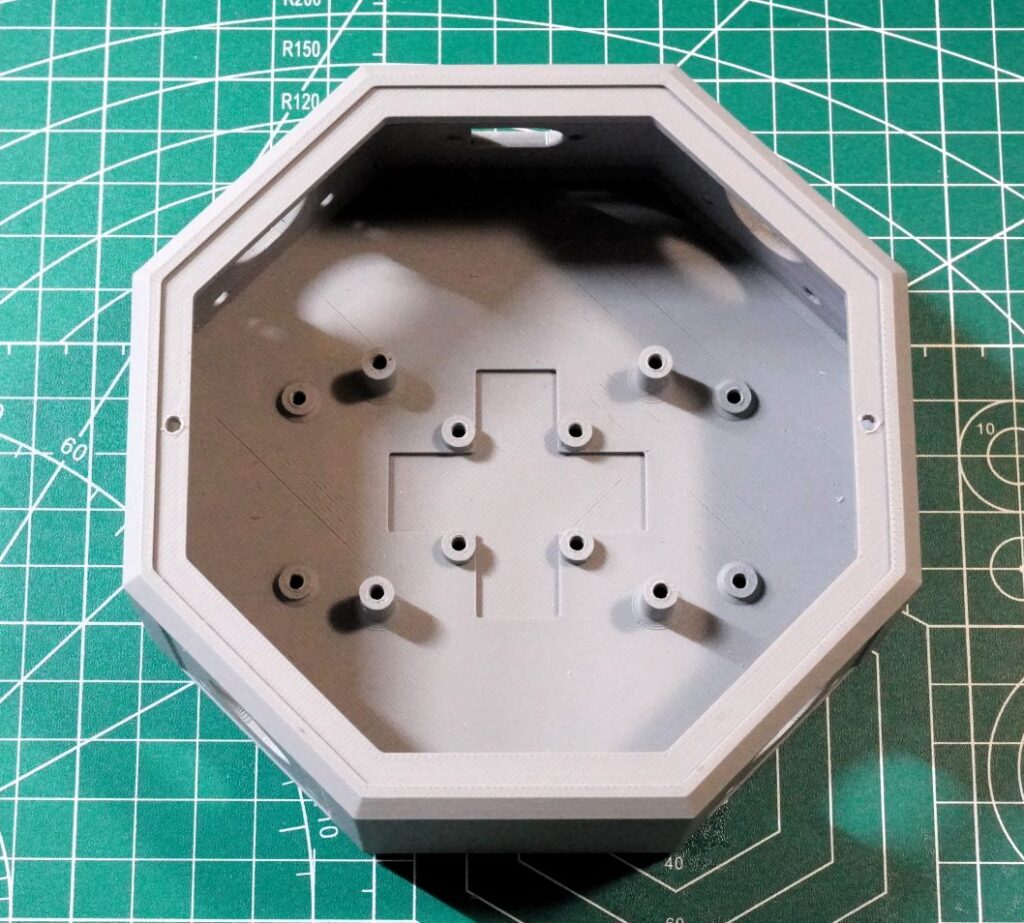

The Fuselage Body has 12 holes in the bottom and 2 holes on the rim to accept M3 screws.

Due to differences in 3D printing tolerances, these holes are slightly undersized.

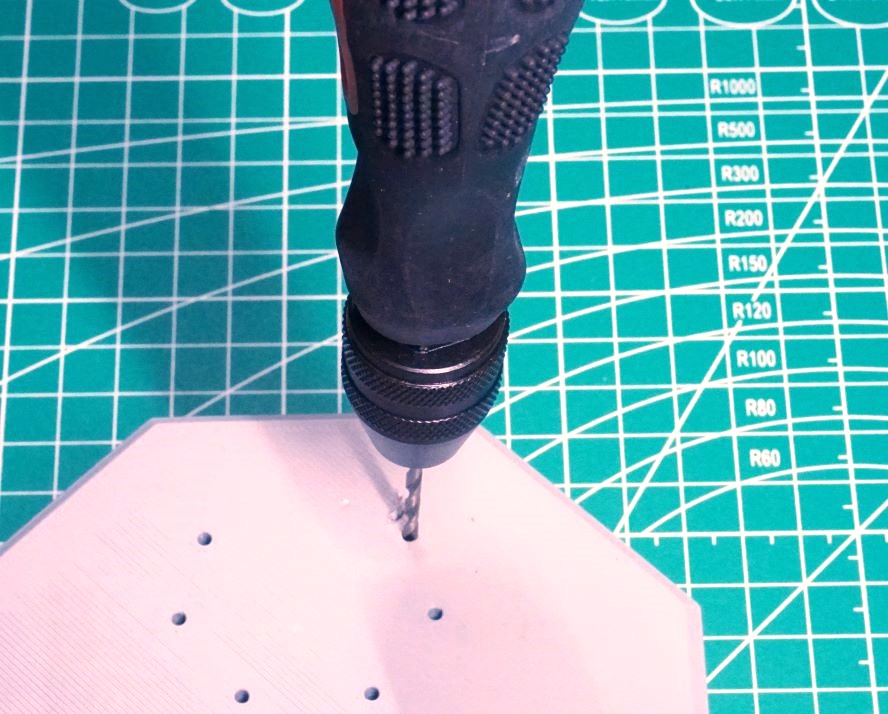

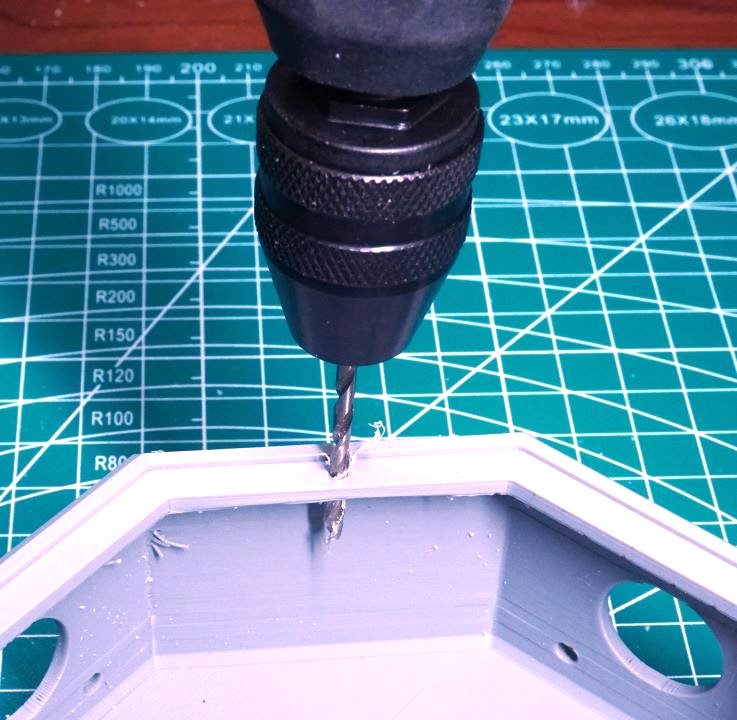

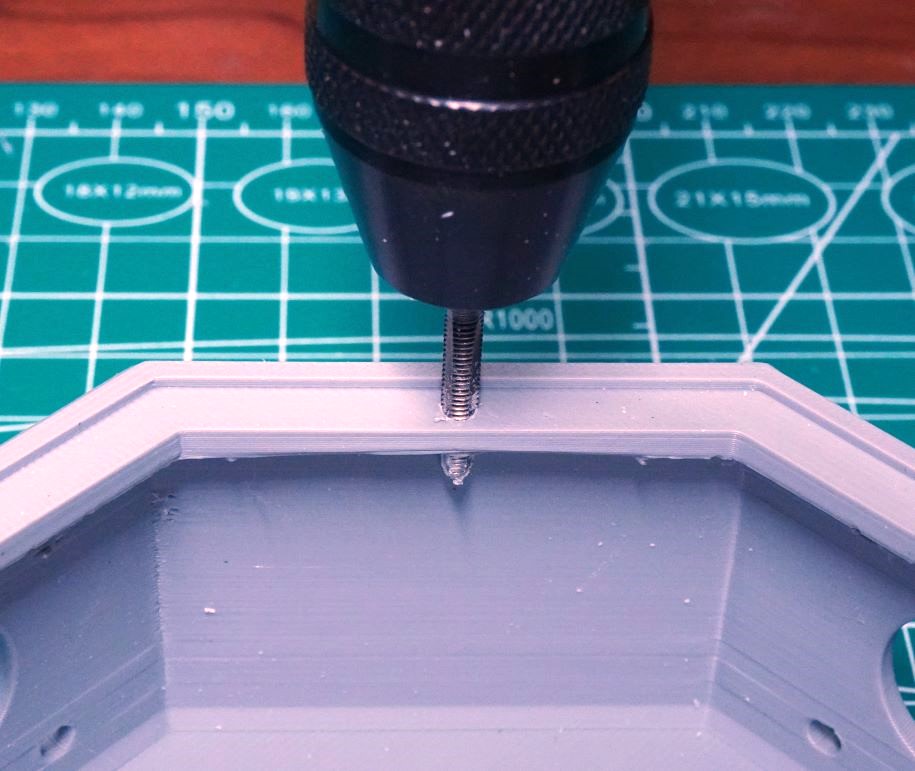

To accept an M3 screw, the holes must first be drilled out to 2.5mm, and then threaded with a M3 tap.

A handheld pin-vice with a 2.5mm drill bit and M3 tap are good tools for preparing the fuselage holes.

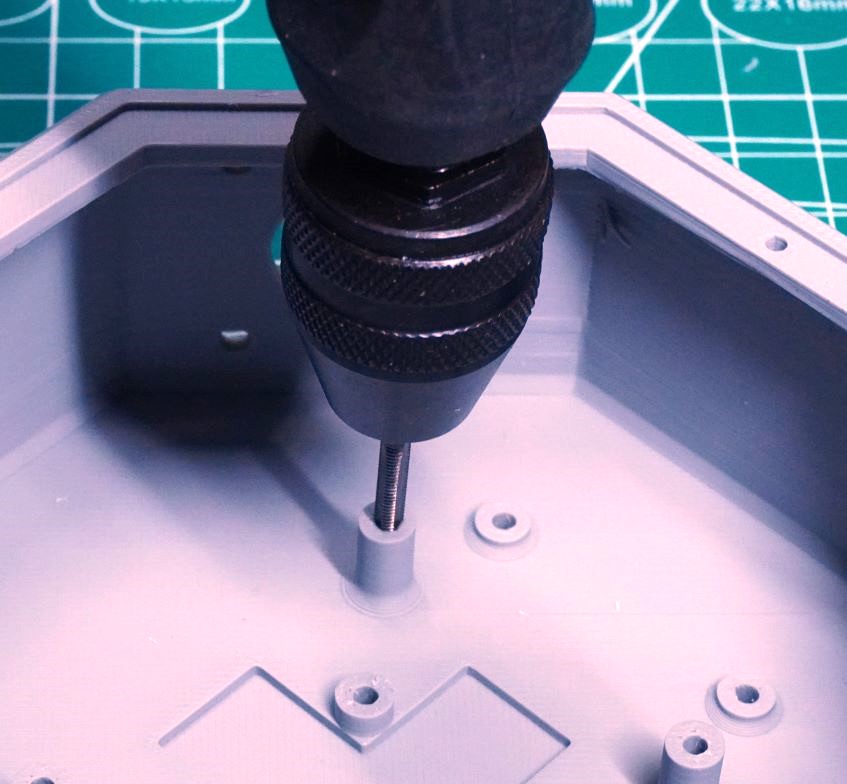

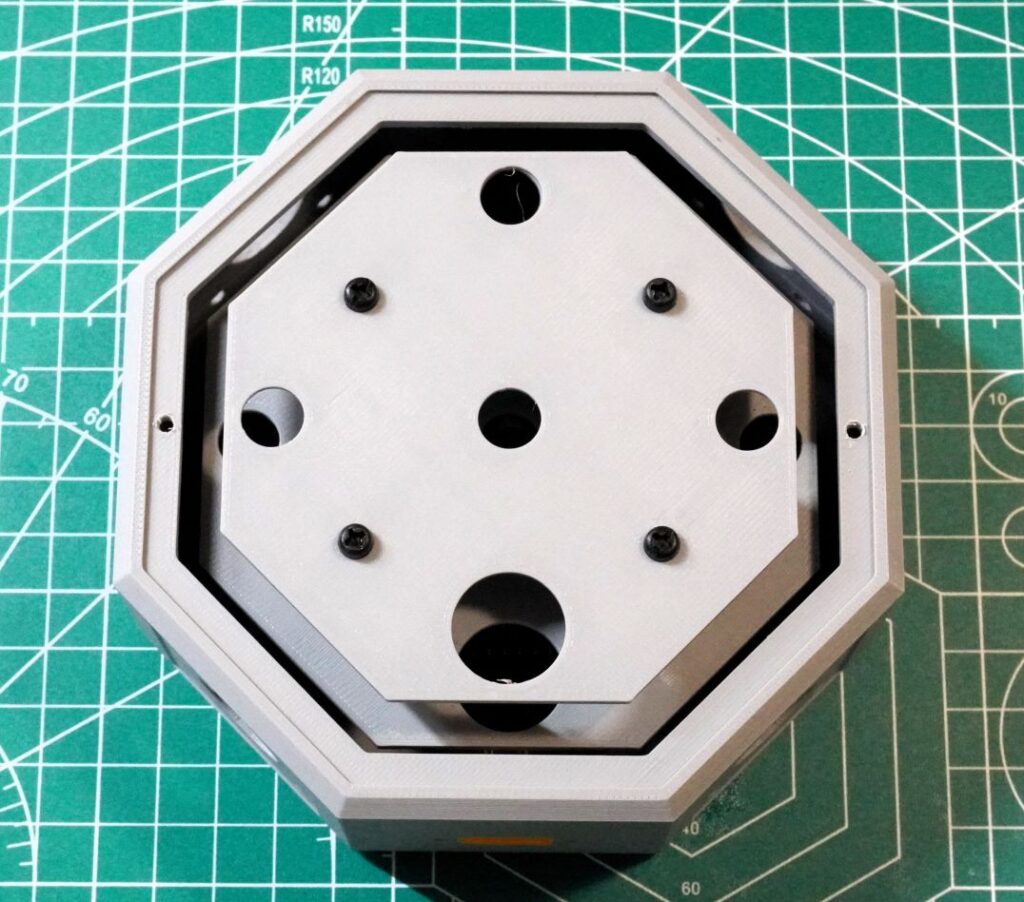

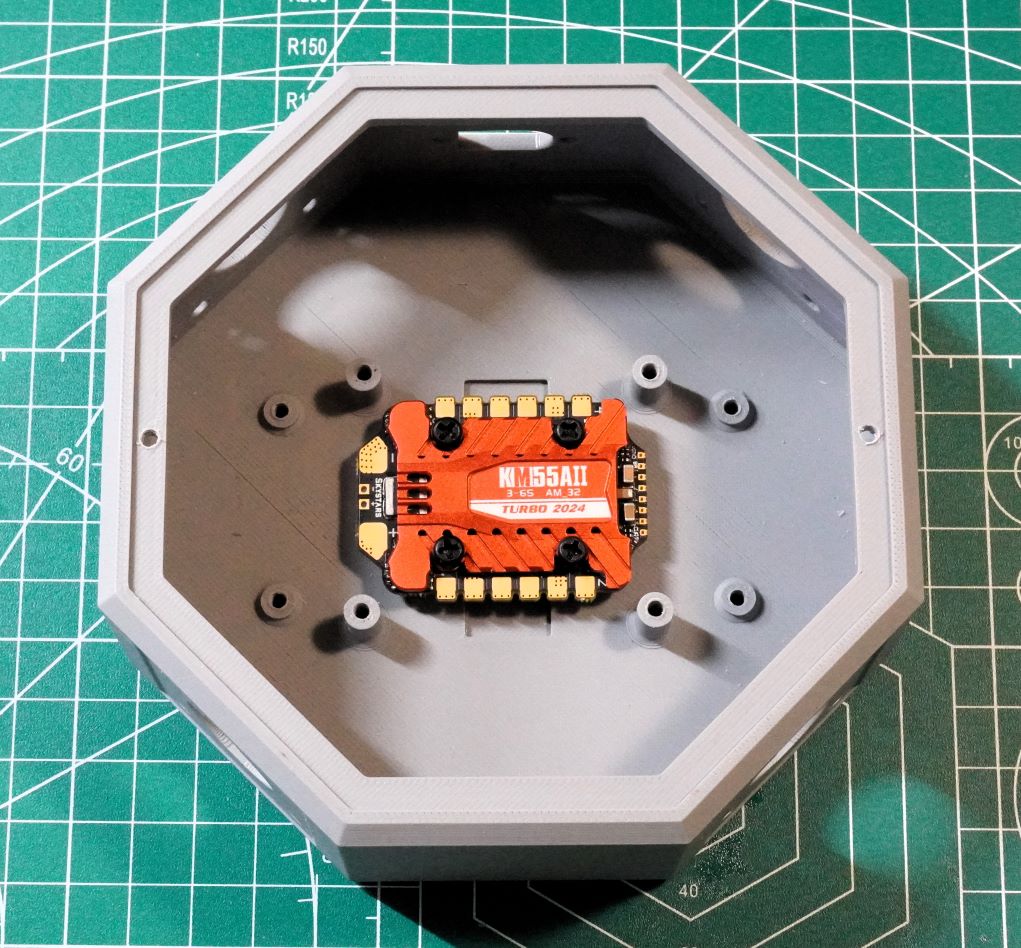

With the holes drilled and tapped, an ESC with a 20×20 mount pattern can be secured with screws.

Here nylon screws are used to avoid possible electrical shorting with the electronics.

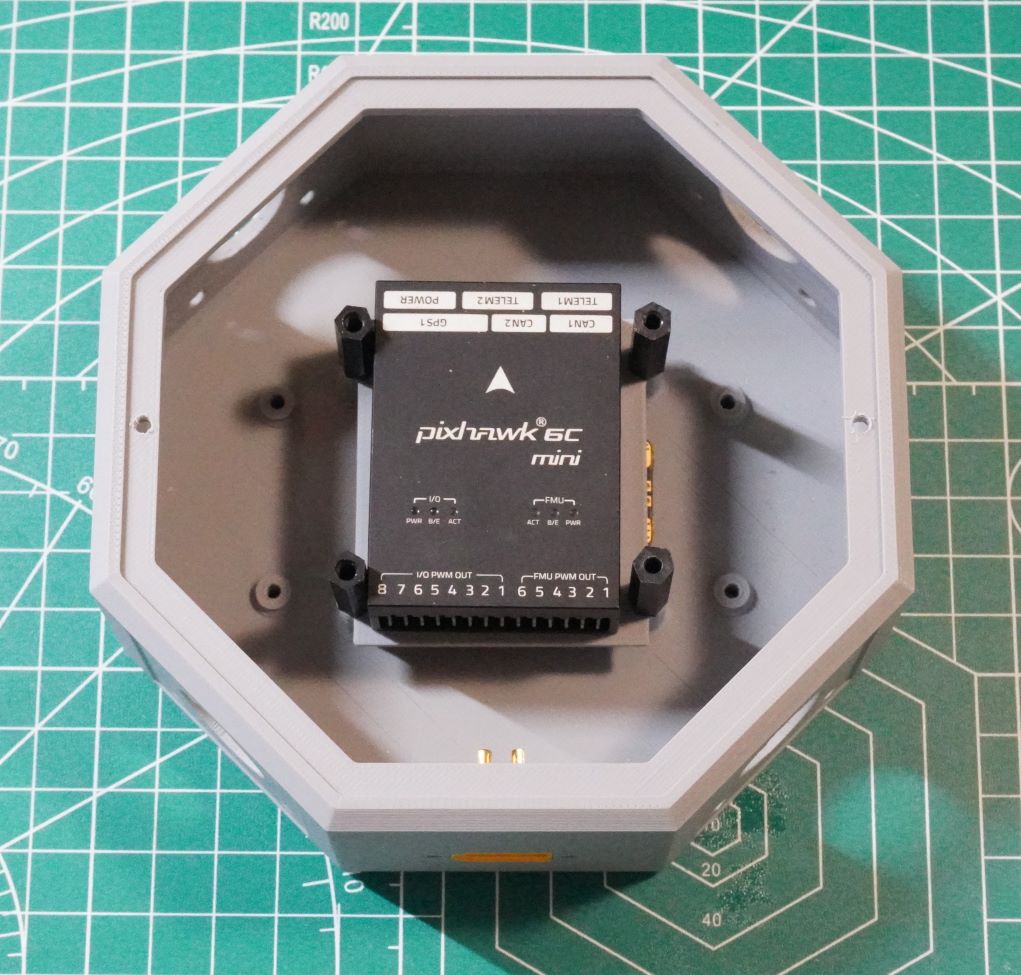

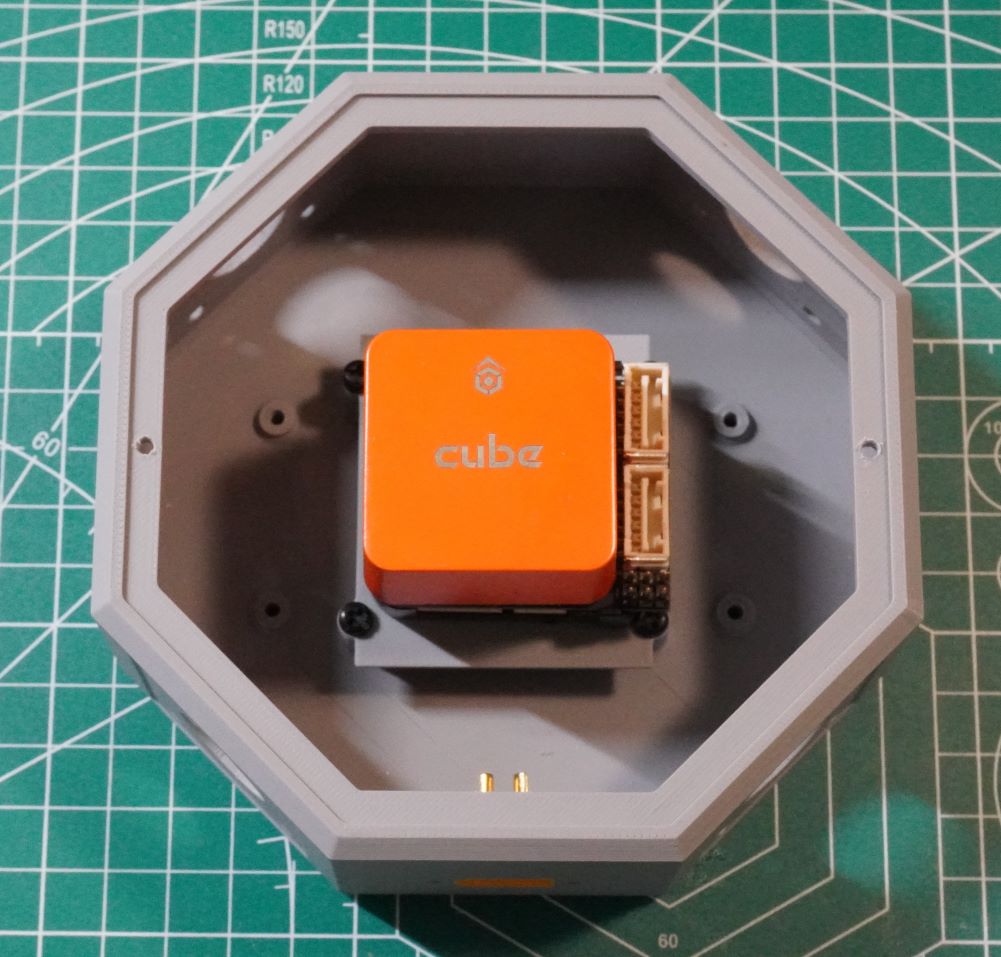

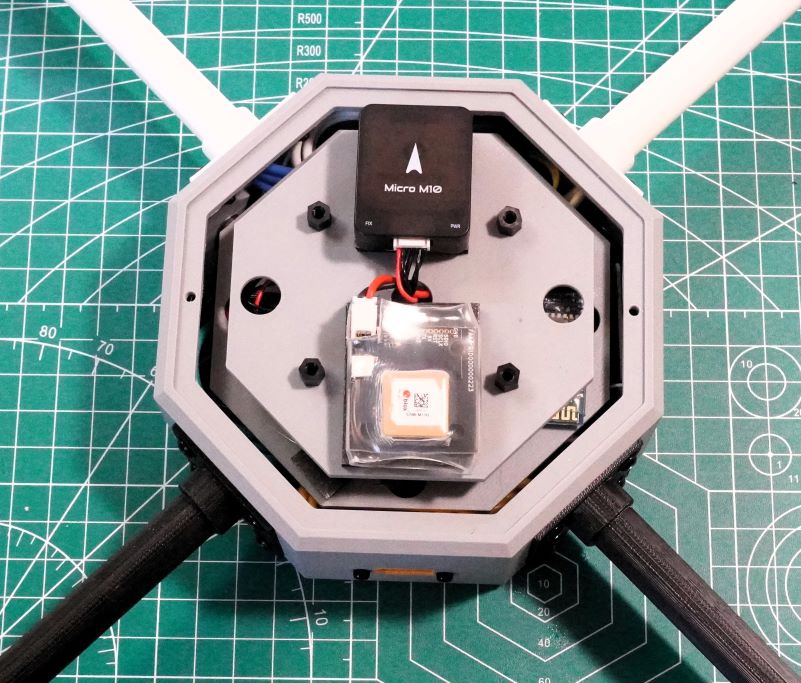

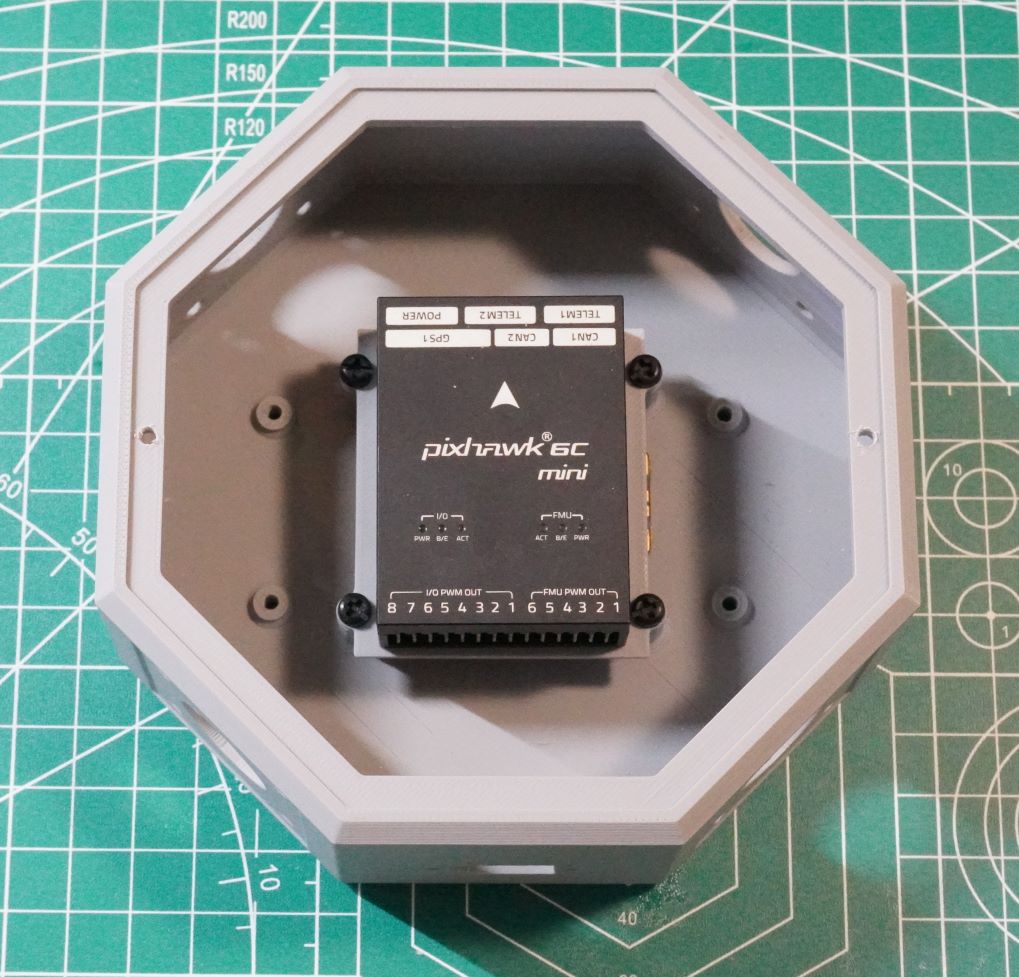

Here is an example of a Holybro Pixhawk 6C Mini on the Flight Controller Tray.

To have proper clearance over the ESC, it may be necessary to place washers between the Flight Controller Tray and the Fuselage mounts. In this example, none were required.

It is possible to secure the Flight Controller Tray with stand-offs to allow mounting an equipment tray above it.