STL files for four Battery Tray sizes and their Door are available for download. Each size it tailored to a specific battery so that it fits in the tray and held in place by the Door.

The four batteries sizes (Length, Width, Height) are:

- Interior Dimensions: 110mm x 40mm x 40mm – fits: RaceDay Quads 4S 2800 mAh LiPo

- Interior Dimensions: 138mm x 38mm x 47mm – fits: RaceDay Quads 4S 5500 mAh LiPo

- Interior Dimensions: 138mm x 43mm x 47mm – fits: RaceDay Quads 4S 6500 mAh HV-LiPo

- Interior Dimensions: 79mm x 39mm x 39mm – fits: Upgrade Energy 4S 4000 mAh Lion

There is a Battery Tray Door associated with each Battery Tray. It’s designed to allow 1mm clearance from the locking “tang” and the side of the tray when properly inserted and locked.

I’ve had good luck printing the battery door using TPU. Since TPU has very strong layer adhesion, I print the Battery Door vertically to minimize support material. That puts pressure on the layers but the TPU has sufficient layer adhesion. If the Battery Door is printed in PLA or other less flexible material, I recommend printing it horizontally so that the layers are not stressed when inserting the “tang” which must flex during insertion.

A battery strap may be used in place of the Door.

- Download STL of Battery Tray – 110mm x 40mm x 40mm

- Download STL of Battery Tray Door – for 110mm x 40mm x 40mm Battery Tray

- Download STL of Battery Tray – 138mm x 38mm x 47mm

- Download STL of Battery Tray Door – for 138mm x 38mm x 47mm Battery Tray

- Download STL of Battery Tray – 138mm x 43mm x 47mm

- Download STL of Battery Tray Door – for 138mm x 43mm x 47mm Battery Tray

- Download STL of Battery Tray – 79mm x 39mm x 39mm

- Download STL of Battery Tray Door for 79mm x 39mm x 39mm Battery Tray

Requests for new sizes are welcome.

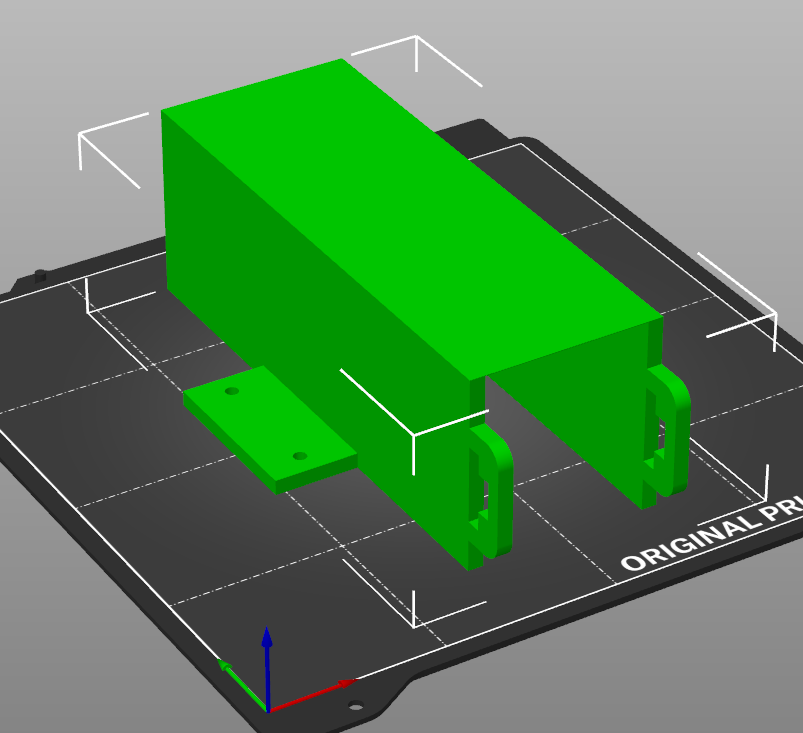

Suggested Print Orientation

This print orientation requires the Battery Tray interior to be filled with supports. However it leaves the mounting ears free of supports and scaring, and when the supports from the interior are removed, any scaring is not seen when the battery is in place.

Another possibility is to print the Battery Tray at a 45 degree angle on a rear corner edge. I’ve not tried this approach personally – but I’ve seen it suggested for prints like this.

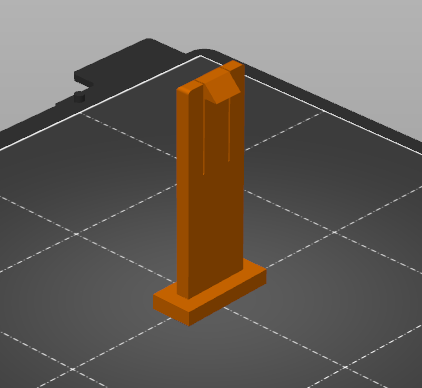

Suggested print orientation for the Battery Tray Door – using TPU:

With this print orientation, the door flexes across the layer lines. TPU has such strong layer adhesion that this hasn’t been a problem on my prints.

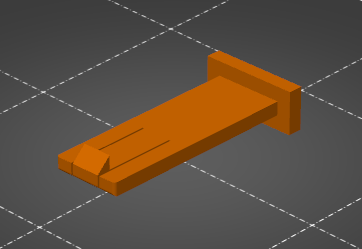

Suggested print orientation for Battery Tray Door – using PLA or other non-flexible material:

This orientation puts layer lines across the direction of flex for the locking tang – so there’s no risk of breaking across the layers. This orientation causes support along one side of the Battery Tray Door – which may require some sanding for smoothness.

As with the Battery Trays – it may be possible to print this part at a 45 degree angle orientation.

The Battery Tray for the 4000 mAh Lion has cooling holes on the sides due to the heat generated during battery discharge during flight. These holes cause considerable support material – and requires some effort to clean them properly.

Suggested Infill

Infill for Battery Trays is 10% to 15% using PLA or similar filament. Suggested infill for Battery Tray Doors using TPU is 50%.